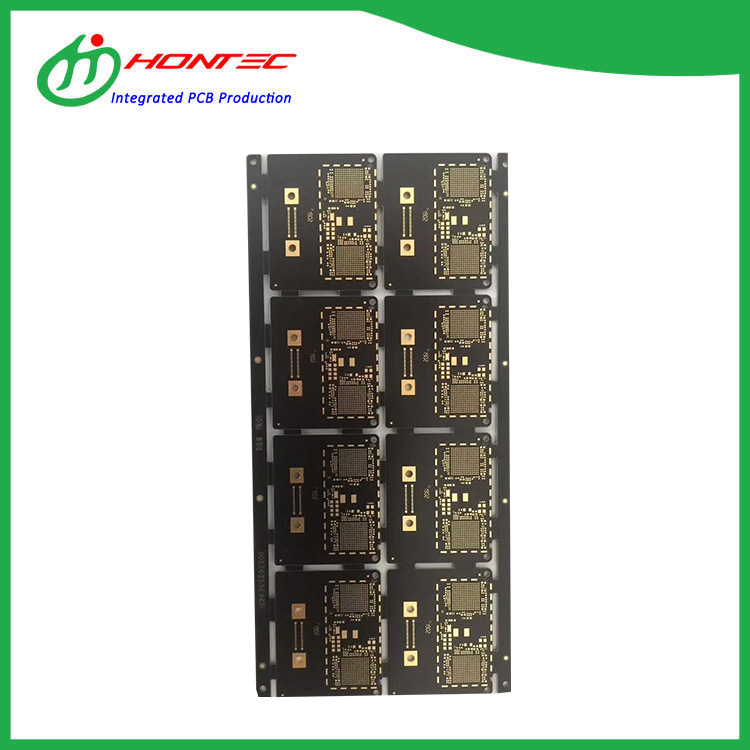

High-Density Interconnect (HDI) PCBs enable revolutionary advancements in electronics by packing intricate circuitry into compact designs. As a leader in HDI PCB manufacturing, HONTEC delivers demanding precision-edge solutions for industries demanding precision, reliability, and rapid innovation. With certifications including UL, SGS, and ISO9001, and streamlined logistics via UPS/DHL, we empower cutting clients across 28 countries. Below, we explore HDI PCB applications, technical specifications, and industry-specific benefits.

HDI PCBs use micro-vias, blind/buried vias, and fine-line traces to achieve higher wiring density than traditional boards. This allows:

Miniaturization: Shrink device sizes by 40–60%.

Enhanced Performance: Reduce signal loss and cross-talk.

Multi-layer Integration: Support complex designs in constrained spaces.

A. Consumer Electronics

Smartphones/Tablets: Enables ultra-thin designs with multi-camera arrays and 5G modules.

Wearables: Powers compact health monitors and AR/VR headsets.

B. Medical Devices

Imaging Systems: MRI machines and portable ultrasound devices.

Implants: Cardiac monitors with biocompatible materials.

C. Automotive Electronics

ADAS: LiDAR sensors and autonomous control units.

Infotainment: High-resolution displays and connectivity hubs.

D. Aerospace & Defense

Avionics: Flight control systems with EMI shielding.

Satellite Comms: Lightweight, radiation-resistant boards.

E. Telecommunications

5G Infrastructure: Base stations and RF amplifiers.

Routers/Switches: High-speed data transmission.

F. Industrial Automation

Robotics: Motor controllers and sensor interfaces.

IoT Gateways: Edge-computing devices.

| Parameter | Standard Range | Advanced Capability |

| Layer Count | 4–20 layers | Up to 30 layers |

| Minimum Trace/Space | 3/3 mil (76.2 μm) | 2/2 mil (50.8 μm) |

| Micro-Via Diameter | 0.1 mm | 0.075 mm |

| Board Thickness | 0.4–3.0 mm | 0.2–5.0 mm |

| Surface Finish | ENIG, HASL, Immersion Silver | OSP, Hard Gold |

| Material | FR-4, High-Tg, Rogers | Polyimide, Halogen-Free |